Apollo del Belvedere

Artist: after Leochares

Date: 2nd century A.D

Classification: Sculpture

Dimensions: 224 cm

Materials: White marble

Adopted By: The Italian & International Chapter

Description

This statue was part of the collection which Cardinal Giuliano della Rovere held in his palace in Rome. When he was elected Pope as Julius II (1503-1513) the statue was transferred to the Vatican, where it has remained since at least 1508.

The god, Apollo, moves forward majestically and seems to have just released an arrow from the bow which he originally carried in his left hand. The work has been dated to mid-way through the 2nd century A.D. and is considered to be a copy of an original bronze statue of 330-320 B.C. by Leochares, one of the artists who worked on the Mausoleum at Halicarnassus.

The statue has always been greatly admired, but owes its fame particularly to Johann Joachim Winckelmann who considered it the sublime expression of Greek art, “of all the works of antiquity that have escaped destruction, the statue of Apollo represents the highest ideal of art.”

Restoration Procedures

The collection and processing of all the scientific data, including the various restoration tests of the study phase preparatory to the intervention, have enabled us to embark on the restoration of the Apollo del Belvedere with a decisive approach. However, a large part of the restoration operations will affect the structural part of the sculpture and will necessarily have to be undertaken after the support structure is in place.

The support structure, following a series of data collection, measurements, 3D scans, as well as considerations elaborated and shared with the Department of Greek and Roman Antiquities, the Marble Restoration Laboratory, and the Scientific Research Laboratory, is being produced by the specialized company Aviacompositi using carbon fiber with steel elements and tie rods.

Such a structure will make it possible to better balance the loads on the sculpture, avoiding the burden mainly on the right leg and the cippus, whose tightness has been severely compromised by the multiple interventions carried out on the sculpture over the centuries.

In the nineteenth century, the sculpture had been fixed to the masonry and base by an iron bar specifically for this purpose. In this regard, the creation of this structure will take place with the close cooperation of the Vatican Museums Directorate.

Detail

Adopted By:

The Italian & International ChapterPatrons:

Bank of America Art Conservation Project 2021

Artist: after Leochares

Date: 2nd century A.D

Dimensions: 224 cm

Materials: White marble

Laboratories:

Stone MaterialsWishbook year: 2021

Apollo del Belvedere - Second Restoration Update

Cast of the hand

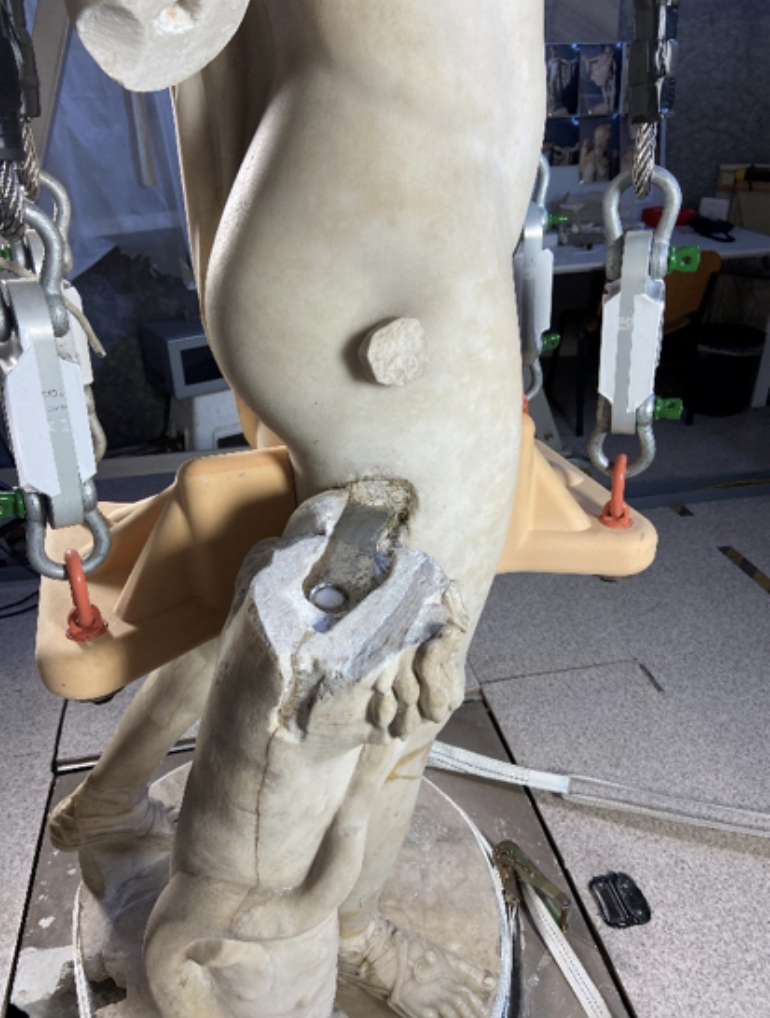

At the same time as these operations, the left hand was removed (restored by Montorsoli) by restorer Andrea Felice, who then proceeded to make a cast of the hand from Baia, probably the original hand of the Apollo of the Belvedere.

This cast was provisionally attached to the forearm of the Apollo placing a steel pin in a pre-existing hole.

This operation will allow the Scientific Research Laboratory to take a 3D photograph and then scan the wrist that connects the hand to the arm, which allows restorers to study and prototype the position and dimensions.

Preparation of the structural elements

Similarly, in collaboration with the Scientific Research Laboratory, a study will be carried out to test the softening of polyester resins with different types of gels (after taking samples to analyze suitable solvents) for all the parts overflowing at the gaps where the resin is extremely thin and for all the fillings to be treated on Apollo's drapery, such as those areas where it is not possible to apply mechanical force.

In close collaboration with restorer Andrea Felice, the company Aviacompositi continues the construction of the complex carbon fiber support structure, attached in the upper part to a steel expansion pin on the pre-existing posterior hole and in the lower part to the previous iron rod seat on the Apollo's base, using custom-made steel plates on the base.

Cleaning

The restorers cleaned the surface after removing the resin fillings from the legs.

In the case of the Apollo del Belvedere, cleaning has never been carried out with any particular care; structural restoration has always been the priority. Over the years, the sculpture, kept in a semi-open environment, was periodically dusted but never cleaned, and after dusting, a protective coating was applied to protect it from atmospheric agents.

For this reason, today, during the cleaning phase, we find ourselves working in a complex way, at different stages, using various methods, because the layers of deposits that are coherent with the surface are composed of different layers: incoherent and coherent powdery deposits, alternating with overlaps of protective agents applied over the years and materials used as release agents for the molding operations.

Surface cleaning at this stage consists of removing the powdery deposits with a latex sponge soaked in hot water, followed by the first application of agar-agar with 3% triammonium citrate added, contact time of 30 minutes.

Restorers then mechanically removed the agar-agar gel, residues, and the remaining part not incorporated in the gel (but softened) using a latex sponge and lukewarm water. This operation allows us to remove the coherent and powdery deposits adhering to the surface. At this stage, when the marble is smoother, we can see the traces of the protective brush strokes on the dirt.

The layer underneath, related to the previous protective layer applied for maintenance, is partially removed by dabbing with soft brushes to support the solvent action of a 50% mixture of ligroin and acetone. This operation is alternated with the application of white spirit on the swab and left to act for 7-8 minutes, then the swab is repeated with acetone and 50% ligroin. These alternations are numerous on all horizontal planes, especially on the upper part of the sculpture, where the marble surface is abraded and eroded. Again, agar-agar gel with 3% triammonium citrate is applied; after 20 minutes, the residue is removed with a latex sponge soaked in warm water, and the surface is wiped with a mixture of ligroin and acetone until the surface is clean.

On the hair, traces of polychromy, already visible during the study phase and analyzed by XRF, were more pronounced, and it would be appropriate to re-analyze the polychromy to obtain better data. On the back of the left arm, after the first phase of the cleaning, the protective brushstrokes are visible in combination with dirt, and the ancient traces of sanguine molding appear immediately in the layer below.

The cleaning is satisfactory but must be carried out with great care. At regular intervals, the Museum's photographic laboratory invites the photographer and the person in charge of video recording to document the restoration work. At the end of March, the Curator of the Greek and Roman Department, Dr. Claudia Valeri, invited Professor Carlo Gasparri to visit the site, and he provided valuable information on Baia's workshops and craftsmen concerning the simulation of the cast of the left hand.

Assembly of the support structure

On Tuesday, May 7, restorer Andrea Felice and Fabio Manieri assembled the support system at the Belvedere Apollo site. They ran a preliminary test assembly to check whether or not further work or modifications were necessary.

All the steel plates were then positioned on the back of the base, together with the carbon fiber rod and the corresponding internal supports and shims. The screw anchoring elements (made reversible by removing the expandable element) and all the supports were correctly positioned without any further intervention or modification.

The expansion element with the cast supports was then located in the hole in the shoulders of the statue. The expansion bolt was loaded 'just enough' to avoid excessive forces. Once this preliminary test was complete, the load cell connection was fitted. We then moved on to the final assembly of the system.

The plates were correctly positioned with the rod, supports, and internal metal shims. The eight Hilti steel expansion inserts were placed to the end (approx. 16 cm) and secured with the appropriate nuts and washers. All bolts were tightened to 30 N/m using a torque wrench.

The internal expansion support with the cast shims was inserted correctly and tightened to a load considered appropriate, without exceeding, to avoid the risk of the resin shims breaking.

The turnbuckle with articulated heads was then attached to the expansion bracket and rod head with a steel bolt and internal spacers. The load cell was connected to the Futek IPM650 reading terminal, and the turnbuckle was initially loaded to 70kg. The full load was applied in several stages to allow the movement of the statue and support to be monitored over a longer period and to allow the structure to settle.

After approximately 16 hours, the load cell indicated a load of 68,225 kg. in a stable position. A further 30 kilograms was loaded, bringing the total load to 100 kg.

Hand simulation through 3D scanning

On May 3, Claudia Valeri (Curator of the Greek and Roman Department), Fabio Morresi (Head of the Scientific Restoration Laboratory), Guy Devreux (Head of the Marble Restoration Laboratory), and restorers Fabio Castro, Valentina Felici, and Andrea Felice met in the diagnostic laboratory to view the 3D scans prepared by Fabio Castro to decide on the correct position of the left hand from the Baia cast. Various hypotheses and possible solutions were proposed to achieve the most anatomically and aesthetically satisfactory position and relationship.

On May 6, Andrea Felice and Fabio Castro developed the best arm-hand model available. Various analytical attempts were unsuccessful, so it was decided to keep the orientation and position of the hand, which had already been simulated, by mounting the cast directly on the scanned statue. The same position of the hand was then adapted to the existing part of the arm by bringing it closer to the 3D model in the correct proportion and distance. A geometric volume was applied to fill the gap between the hand and the arm to provide a full volume and a complete view. The position considered correct was analyzed from three different angles.

Apollo del Belvedere - Restoration Update

The restorers uncovered bars and pins, and holes related to previous restoration work; in all critical areas, while waiting for the new support structure, the fillings were lowered, allowing the original areas to emerge, to determine the extent of the reintegrations.

One of the goals of the intervention currently in progress is to restore all the elements with a load-bearing function that gives "stability" to the statute. The first steel bracket has already been made, thanks to the collaboration with our mechanical workshop (image 8).

Restorers will first lower the stucco on all areas involving the legs (from the knees to the ankles), and then remove it when the sculpture is protected by the support structure. As for diagnostic investigations, an additional radiographic campaign will be carried out in the coming days.

Apollo del Belvedere

Details

Adopted by: The Italian & International Chapter

Patrons: Bank of America Art Conservation Project 2021

Artist: after Leochares

Date: 2nd century A.D

Classification: Sculpture

Materials: White marble

Dimensions: 224 cm

Laboratory: Stone Materials

Wishbook year: 2021

Description

This statue was part of the collection which Cardinal Giuliano della Rovere held in his palace in Rome. When he was elected Pope as Julius II (1503-1513) the statue was transferred to the Vatican, where it has remained since at least 1508.

The god, Apollo, moves forward majestically and seems to have just released an arrow from the bow which he originally carried in his left hand. The work has been dated to mid-way through the 2nd century A.D. and is considered to be a copy of an original bronze statue of 330-320 B.C. by Leochares, one of the artists who worked on the Mausoleum at Halicarnassus.

The statue has always been greatly admired, but owes its fame particularly to Johann Joachim Winckelmann who considered it the sublime expression of Greek art, “of all the works of antiquity that have escaped destruction, the statue of Apollo represents the highest ideal of art.”

Restoration Procedures

The collection and processing of all the scientific data, including the various restoration tests of the study phase preparatory to the intervention, have enabled us to embark on the restoration of the Apollo del Belvedere with a decisive approach. However, a large part of the restoration operations will affect the structural part of the sculpture and will necessarily have to be undertaken after the support structure is in place.

The support structure, following a series of data collection, measurements, 3D scans, as well as considerations elaborated and shared with the Department of Greek and Roman Antiquities, the Marble Restoration Laboratory, and the Scientific Research Laboratory, is being produced by the specialized company Aviacompositi using carbon fiber with steel elements and tie rods.

Such a structure will make it possible to better balance the loads on the sculpture, avoiding the burden mainly on the right leg and the cippus, whose tightness has been severely compromised by the multiple interventions carried out on the sculpture over the centuries.

In the nineteenth century, the sculpture had been fixed to the masonry and base by an iron bar specifically for this purpose. In this regard, the creation of this structure will take place with the close cooperation of the Vatican Museums Directorate.

Media

Apollo del Belvedere

Restorations Update: Apollo del Belvedere - Second Restoration Update

Cast of the hand

At the same time as these operations, the left hand was removed (restored by Montorsoli) by restorer Andrea Felice, who then proceeded to make a cast of the hand from Baia, probably the original hand of the Apollo of the Belvedere.

This cast was provisionally attached to the forearm of the Apollo placing a steel pin in a pre-existing hole.

This operation will allow the Scientific Research Laboratory to take a 3D photograph and then scan the wrist that connects the hand to the arm, which allows restorers to study and prototype the position and dimensions.

Preparation of the structural elements

Similarly, in collaboration with the Scientific Research Laboratory, a study will be carried out to test the softening of polyester resins with different types of gels (after taking samples to analyze suitable solvents) for all the parts overflowing at the gaps where the resin is extremely thin and for all the fillings to be treated on Apollo's drapery, such as those areas where it is not possible to apply mechanical force.

In close collaboration with restorer Andrea Felice, the company Aviacompositi continues the construction of the complex carbon fiber support structure, attached in the upper part to a steel expansion pin on the pre-existing posterior hole and in the lower part to the previous iron rod seat on the Apollo's base, using custom-made steel plates on the base.

Cleaning

The restorers cleaned the surface after removing the resin fillings from the legs.

In the case of the Apollo del Belvedere, cleaning has never been carried out with any particular care; structural restoration has always been the priority. Over the years, the sculpture, kept in a semi-open environment, was periodically dusted but never cleaned, and after dusting, a protective coating was applied to protect it from atmospheric agents.

For this reason, today, during the cleaning phase, we find ourselves working in a complex way, at different stages, using various methods, because the layers of deposits that are coherent with the surface are composed of different layers: incoherent and coherent powdery deposits, alternating with overlaps of protective agents applied over the years and materials used as release agents for the molding operations.

Surface cleaning at this stage consists of removing the powdery deposits with a latex sponge soaked in hot water, followed by the first application of agar-agar with 3% triammonium citrate added, contact time of 30 minutes.

Restorers then mechanically removed the agar-agar gel, residues, and the remaining part not incorporated in the gel (but softened) using a latex sponge and lukewarm water. This operation allows us to remove the coherent and powdery deposits adhering to the surface. At this stage, when the marble is smoother, we can see the traces of the protective brush strokes on the dirt.

The layer underneath, related to the previous protective layer applied for maintenance, is partially removed by dabbing with soft brushes to support the solvent action of a 50% mixture of ligroin and acetone. This operation is alternated with the application of white spirit on the swab and left to act for 7-8 minutes, then the swab is repeated with acetone and 50% ligroin. These alternations are numerous on all horizontal planes, especially on the upper part of the sculpture, where the marble surface is abraded and eroded. Again, agar-agar gel with 3% triammonium citrate is applied; after 20 minutes, the residue is removed with a latex sponge soaked in warm water, and the surface is wiped with a mixture of ligroin and acetone until the surface is clean.

On the hair, traces of polychromy, already visible during the study phase and analyzed by XRF, were more pronounced, and it would be appropriate to re-analyze the polychromy to obtain better data. On the back of the left arm, after the first phase of the cleaning, the protective brushstrokes are visible in combination with dirt, and the ancient traces of sanguine molding appear immediately in the layer below.

The cleaning is satisfactory but must be carried out with great care. At regular intervals, the Museum's photographic laboratory invites the photographer and the person in charge of video recording to document the restoration work. At the end of March, the Curator of the Greek and Roman Department, Dr. Claudia Valeri, invited Professor Carlo Gasparri to visit the site, and he provided valuable information on Baia's workshops and craftsmen concerning the simulation of the cast of the left hand.

Assembly of the support structure

On Tuesday, May 7, restorer Andrea Felice and Fabio Manieri assembled the support system at the Belvedere Apollo site. They ran a preliminary test assembly to check whether or not further work or modifications were necessary.

All the steel plates were then positioned on the back of the base, together with the carbon fiber rod and the corresponding internal supports and shims. The screw anchoring elements (made reversible by removing the expandable element) and all the supports were correctly positioned without any further intervention or modification.

The expansion element with the cast supports was then located in the hole in the shoulders of the statue. The expansion bolt was loaded 'just enough' to avoid excessive forces. Once this preliminary test was complete, the load cell connection was fitted. We then moved on to the final assembly of the system.

The plates were correctly positioned with the rod, supports, and internal metal shims. The eight Hilti steel expansion inserts were placed to the end (approx. 16 cm) and secured with the appropriate nuts and washers. All bolts were tightened to 30 N/m using a torque wrench.

The internal expansion support with the cast shims was inserted correctly and tightened to a load considered appropriate, without exceeding, to avoid the risk of the resin shims breaking.

The turnbuckle with articulated heads was then attached to the expansion bracket and rod head with a steel bolt and internal spacers. The load cell was connected to the Futek IPM650 reading terminal, and the turnbuckle was initially loaded to 70kg. The full load was applied in several stages to allow the movement of the statue and support to be monitored over a longer period and to allow the structure to settle.

After approximately 16 hours, the load cell indicated a load of 68,225 kg. in a stable position. A further 30 kilograms was loaded, bringing the total load to 100 kg.

Hand simulation through 3D scanning

On May 3, Claudia Valeri (Curator of the Greek and Roman Department), Fabio Morresi (Head of the Scientific Restoration Laboratory), Guy Devreux (Head of the Marble Restoration Laboratory), and restorers Fabio Castro, Valentina Felici, and Andrea Felice met in the diagnostic laboratory to view the 3D scans prepared by Fabio Castro to decide on the correct position of the left hand from the Baia cast. Various hypotheses and possible solutions were proposed to achieve the most anatomically and aesthetically satisfactory position and relationship.

On May 6, Andrea Felice and Fabio Castro developed the best arm-hand model available. Various analytical attempts were unsuccessful, so it was decided to keep the orientation and position of the hand, which had already been simulated, by mounting the cast directly on the scanned statue. The same position of the hand was then adapted to the existing part of the arm by bringing it closer to the 3D model in the correct proportion and distance. A geometric volume was applied to fill the gap between the hand and the arm to provide a full volume and a complete view. The position considered correct was analyzed from three different angles.

Restorations Update: Apollo del Belvedere - Restoration Update

The restorers uncovered bars and pins, and holes related to previous restoration work; in all critical areas, while waiting for the new support structure, the fillings were lowered, allowing the original areas to emerge, to determine the extent of the reintegrations.

One of the goals of the intervention currently in progress is to restore all the elements with a load-bearing function that gives "stability" to the statute. The first steel bracket has already been made, thanks to the collaboration with our mechanical workshop (image 8).

Restorers will first lower the stucco on all areas involving the legs (from the knees to the ankles), and then remove it when the sculpture is protected by the support structure. As for diagnostic investigations, an additional radiographic campaign will be carried out in the coming days.

© 2026 Patrons of the Arts

in the Vatican Museums

Vatican Museums V-00120,

Vatican City State (Europe)

+39 0669864499